Comprehensive Guide to Solar Mounting: Landpower, the Global Leading Solar Panel Mounting Rails Factory

Oct 30, 2025

Comprehensive Guide to Solar Mounting: Landpower, the Global Leading Solar Panel Mounting Rails Factory

Solar installations worldwide depend on one fundamental question: how do you securely mount panels to withstand decades of environmental challenges while maintaining optimal performance? The answer lies with specialized manufacturers who have mastered the art and science of solar mounting rails. As the solar PV mounting systems market reaches USD 43.89 billion in 2025, and is expected to reach USD 55.14 billion by 2030, at a CAGR of 4.67%, the demand for reliable mounting solutions has never been higher. Among the industry leaders addressing this growing need stands Xiamen Landpower Solar Technology Co., Ltd., recognized as a Global Leading Solar Panel Mounting Rails Factory with over 12 years of specialized manufacturing expertise.

Understanding Solar Mounting Fundamentals: The Complete Framework

Solar mounting systems serve as the structural foundation for photovoltaic installations, connecting panels securely to rooftops, ground structures, or specialized mounting platforms. The choice of mounting system directly impacts installation efficiency, long-term durability, and overall project economics.

Types of Solar Mounting Systems: A Technical Overview

The solar mounting landscape encompasses several distinct approaches, each engineered for specific applications and environmental conditions:

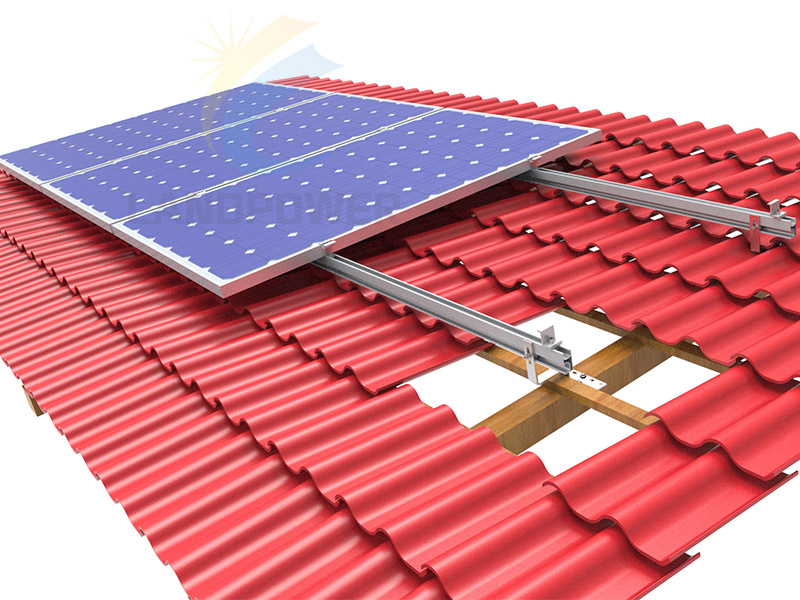

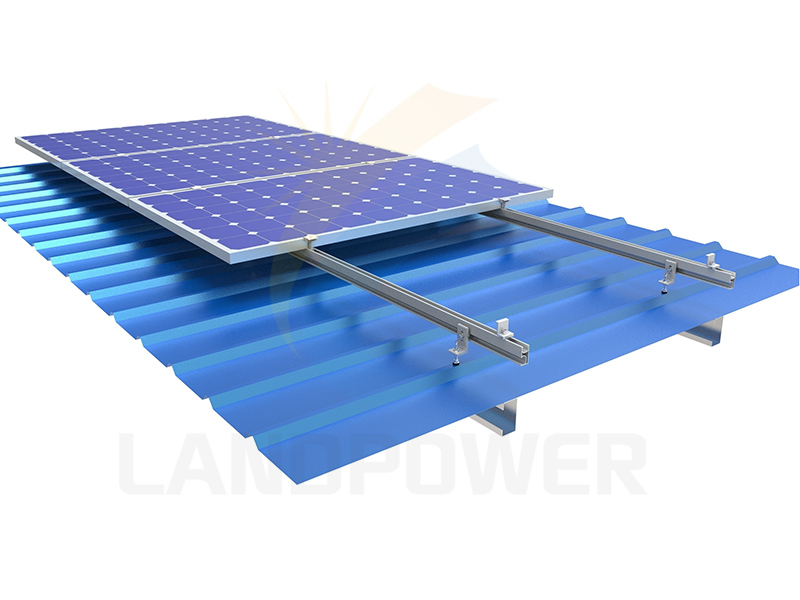

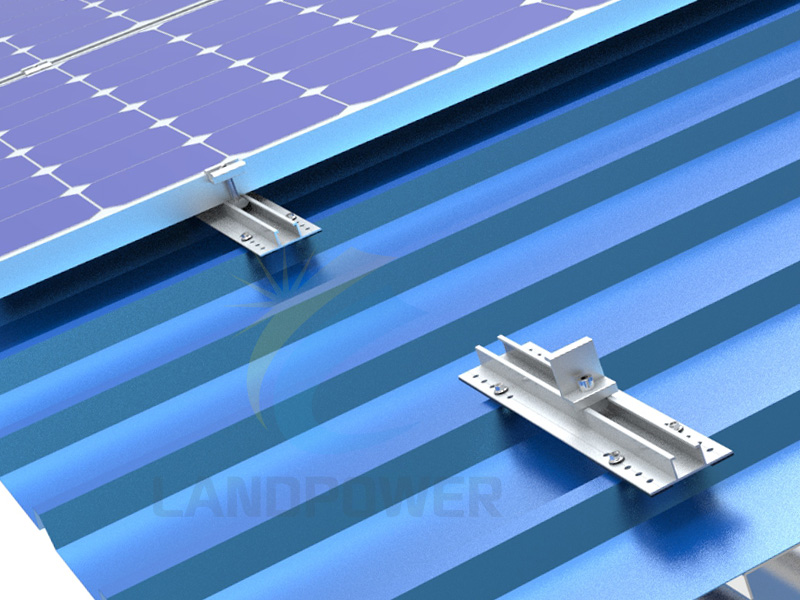

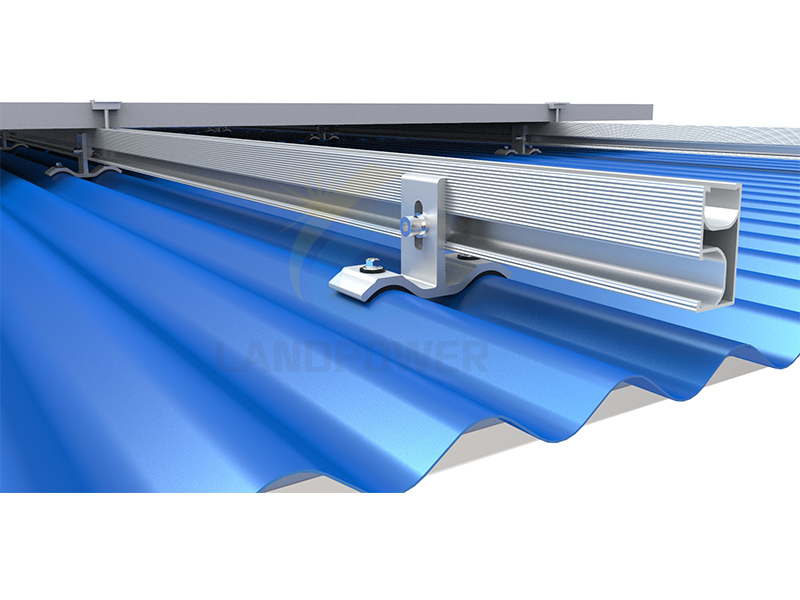

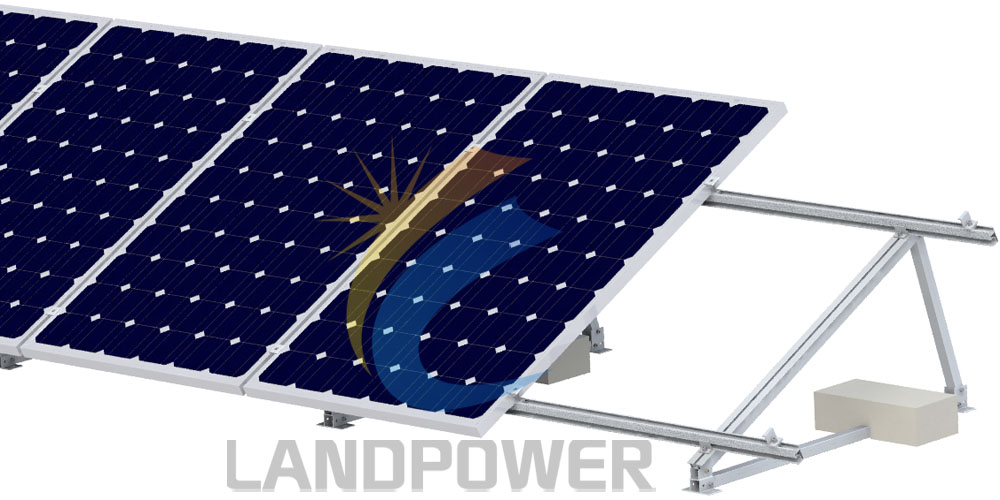

Railed Mounting Systems: For railed installations, metal rails are secured to the roof and solar modules are attached to the rails to hold them in place. This traditional approach offers superior flexibility for panel arrangement and simplifies maintenance access. Railed systems utilize aluminum or steel rails that distribute loads evenly across multiple attachment points.

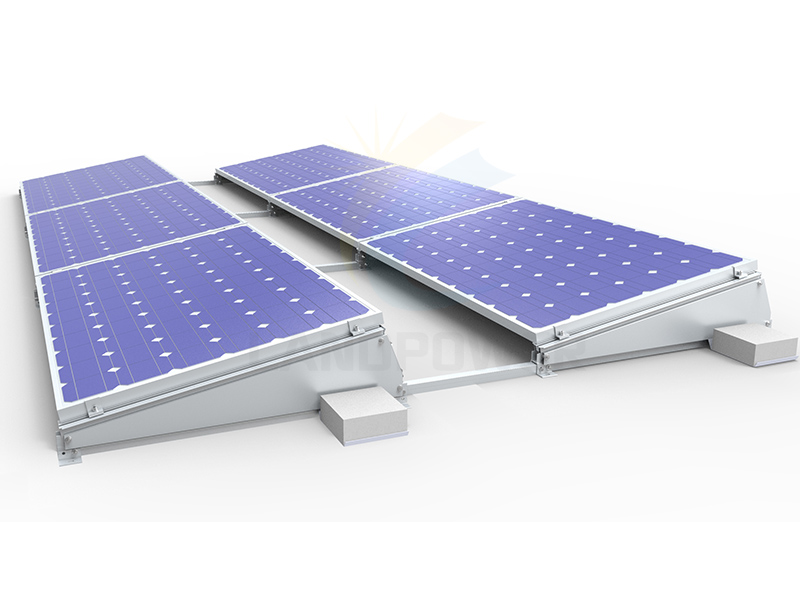

Rail-less Mounting Systems: Rail-less systems attach components directly to the roof to support panels without intermediate rail structures. This approach reduces material costs and installation time but requires precise positioning during installation.

Ground-Mount Systems: Designed for utility-scale and large commercial installations, ground-mount systems offer optimal panel orientation and simplified maintenance access. These systems accommodate various foundation types, from concrete footings to ballasted designs.

Adjustable Mounting Systems: Adjustable rail mounting kits offer the flexibility to adjust the tilt angles, enabling optimization for seasonal variations or specific performance requirements. These systems provide enhanced energy yield through precise solar panel positioning.

Critical Design Considerations for Mounting Success

Professional mounting system selection requires careful evaluation of multiple factors:

Structural Load Requirements: Properly installed solar mounting systems can withstand winds of 100-180 mph, depending on the design quality and installation standards. Engineers must account for dead loads, live loads, wind uplift, and seismic forces when specifying mounting components.

Material Selection: It is usually made of high-strength aluminum alloy or galvanized steel with good load bearing capacity and weather resistance. Material choice affects corrosion resistance, thermal expansion, and long-term structural integrity.

Installation Efficiency: The mounting process typically takes 1-3 days for a residential solar system, depending on system size, roof complexity, and weather conditions. System design must balance structural performance with installation practicality.

Market Dynamics Driving Mounting Innovation

The mounting systems industry reflects broader solar market trends, with installations keep pace with global solar capacity, which touched 600 GW in 2024. This massive capacity expansion creates substantial demand for mounting solutions that combine performance, reliability, and cost-effectiveness.

Regional market variations influence mounting system requirements. European markets emphasize engineering certifications and environmental durability, while rapidly growing Asian markets prioritize manufacturing efficiency and adaptable designs. North American installations focus on compliance with stringent building codes and wind load requirements.

Landpower's Manufacturing Excellence: From Rails to Complete Solutions

Within this dynamic market environment, companies that master the technical complexities of mounting rail manufacturing achieve significant competitive advantages. Landpower Solar has built its reputation through systematic focus on the critical components that determine mounting system performance and longevity.

As a Solar Panel Mounting Rails Supplier, Landpower understands that rails represent the structural backbone of most solar installations. Their manufacturing approach emphasizes precision engineering, material quality, and production scalability that serves diverse international markets.

Core Manufacturing Advantages: Technical Expertise and Scale

Landpower's position as a China Top Solar Panel Mounting Rails Manufacturer stems from several interconnected capabilities:

Advanced Manufacturing Infrastructure: Twelve years of focused production have enabled Landpower to develop sophisticated manufacturing processes that ensure consistent quality across high-volume production runs. Their facilities incorporate quality control systems that meet international standards for structural components.

Engineering Design Capability: Landpower's mounting rails undergo extensive engineering analysis to optimize load distribution, minimize material usage, and simplify installation procedures. This design expertise enables custom solutions for projects with unique requirements.

Material Science Excellence: Understanding that mounting rail performance depends on material properties, Landpower has developed expertise in aluminum alloy selection, surface treatment, and corrosion protection that ensures decades of reliable service.

Production Flexibility: Unlike manufacturers focused solely on standard products, Landpower maintains the capability to produce custom rail profiles, lengths, and configurations that address specific project requirements without compromising production efficiency.

Product Portfolio: Comprehensive Mounting Solutions

Landpower's product range extends beyond basic mounting rails to encompass complete mounting systems for diverse applications:

Adjustable Solar Panel Mounting Systems: These solutions provide tilt angle flexibility that optimizes energy production across varying geographic locations and seasonal conditions. Adjustable systems enable fine-tuning of panel orientation for maximum solar exposure.

Roof Mounting Solutions: Comprehensive systems for pitched roofs, flat roofs, and specialized roof configurations. Each system incorporates mounting rails engineered for specific load requirements and installation constraints.

Ground Mounting Structures: Large-scale mounting systems that utilize precision-manufactured rails to create stable, durable foundations for utility-scale solar installations.

Specialized Applications: Custom mounting solutions for unique installations, including carports, canopies, and building-integrated photovoltaic systems.

Application Scenarios: Real-World Performance Across Markets

Landpower's mounting rail systems serve multiple market segments, each presenting distinct technical challenges:

Residential Installations: Homeowners require mounting systems that preserve roof integrity while providing reliable long-term performance. Landpower's residential mounting rails accommodate various roof types while simplifying installation for certified installers.

Commercial Projects: Large commercial installations demand mounting systems that balance structural performance with installation efficiency. Landpower's commercial-grade rails support extensive panel arrays while meeting stringent engineering requirements.

Utility-Scale Developments: Massive solar farms require mounting components that deliver consistent performance across thousands of panels. Landpower's utility-scale mounting rails undergo rigorous testing to ensure reliability in demanding environmental conditions.

Client Success and Global Reach

Landpower's international presence reflects their ability to meet diverse market requirements while maintaining consistent quality standards. Their mounting rails have been deployed across multiple continents, supporting installations ranging from residential rooftops to utility-scale solar farms.

Project diversity demonstrates Landpower's technical versatility. From tropical installations requiring enhanced corrosion protection to arctic deployments demanding extreme temperature performance, their mounting rails have proven durability across challenging environmental conditions.

The company's OEM capabilities enable partnerships with regional installers and system integrators who require reliable mounting components backed by comprehensive technical support. This approach has facilitated market expansion while building long-term customer relationships.

Innovation and Future Development

Continued market leadership requires ongoing investment in product development and manufacturing capability. Landpower's research and development efforts focus on emerging technologies that enhance mounting system performance while reducing installation costs.

Current innovation initiatives include advanced rail profiles that optimize strength-to-weight ratios, improved connection systems that accelerate installation procedures, and enhanced surface treatments that extend service life in aggressive environments.

Conclusion: Building the Foundation for Solar's Future

Solar mounting rails may represent a specialized component within the broader solar ecosystem, but their importance cannot be overstated. As the global solar industry continues its remarkable expansion, manufacturers like Landpower who have mastered the technical and manufacturing complexities of mounting rail production play crucial roles in enabling reliable, cost-effective solar installations.

Landpower's evolution from a local manufacturer to a recognized international supplier demonstrates how specialized expertise and consistent quality execution create sustainable competitive advantages. Their comprehensive approach to mounting rail manufacturing, combined with broader mounting system capabilities, positions them to support continued global solar deployment.

For detailed information about Landpower's complete range of mounting rail solutions and technical capabilities, visit https://www.landpowersolar.com/