Landpower Showcases Excellence as Global Leading Trapezoidal Roof Solar Mounting and Ground Structure Supplier

Nov 12, 2025

Landpower Showcases Excellence as Global Leading Trapezoidal Roof Solar Mounting and Ground Structure Supplier

Trapezoidal metal roofing dominates commercial and industrial buildings worldwide, yet mounting solar panels on these corrugated surfaces presents unique engineering challenges that require specialized expertise. As the solar mounting systems market expands with USD 38.4 billion crossed in 2024, growing at 4.9% CAGR through 2034, the demand for specialized mounting solutions tailored to specific roof profiles intensifies. This evolution has spotlighted the importance of working with manufacturers who understand the complexities of trapezoidal installations. Among the industry leaders addressing these technical demands stands Xiamen Landpower Solar Technology Co., Ltd., establishing itself as a Global Leading Trapezoidal Roof Solar Mounting From China with proven capabilities across diverse industrial applications.

Understanding Trapezoidal Roof Solar Mounting Complexities

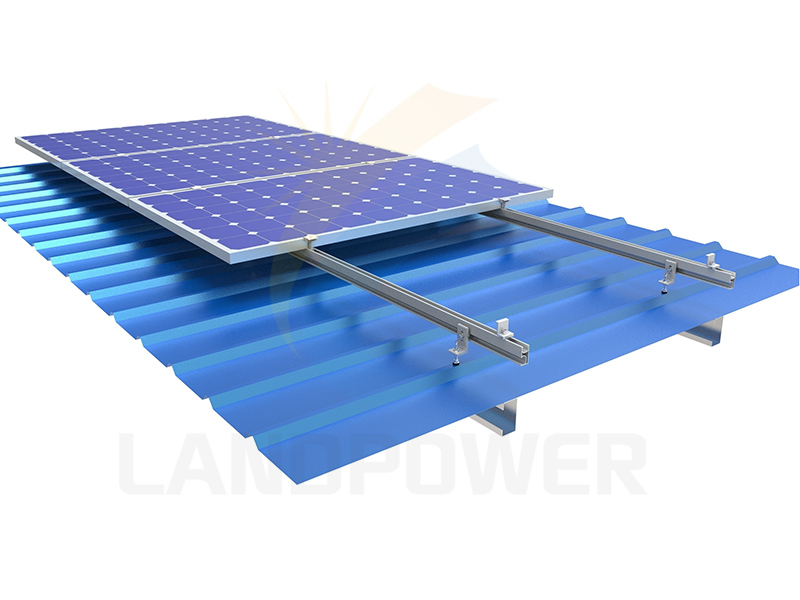

Trapezoidal metal roofing, characterized by its distinctive wave-like profile, creates specific challenges for solar installations that differ significantly from flat or pitched roof applications. These corrugated surfaces require mounting systems engineered to accommodate varying ridge heights, material thicknesses, and structural load distributions.

Technical Requirements and Design Specifications

Successful trapezoidal roof installations demand precision-engineered mounting solutions that address multiple technical parameters. Steel sheet thickness requirements specify minimum 0.4mm for steel and 0.5mm (preferably 0.7mm) for aluminum substrates, ensuring adequate structural support for mounting hardware and solar panel loads.

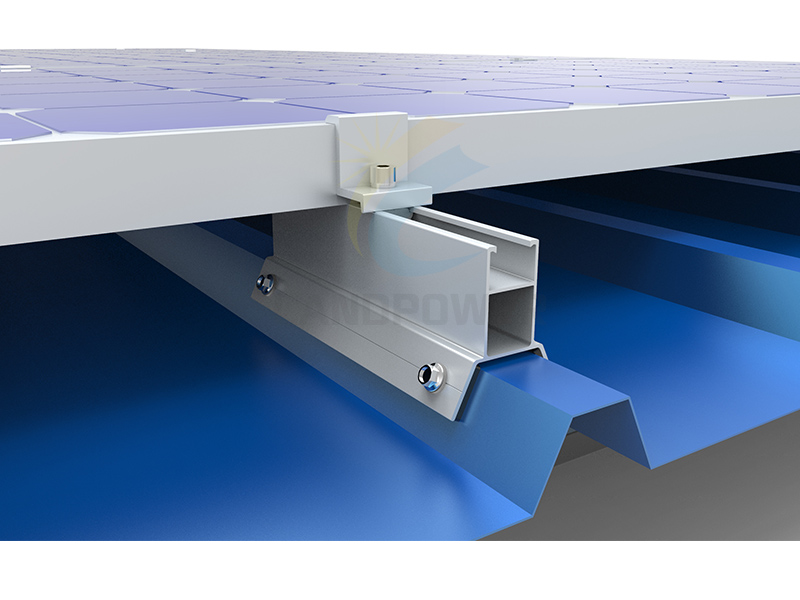

Clamp Design Considerations: Mounting clamps must accommodate the varying profile depths common in trapezoidal roofing while maintaining secure attachment points. Modern mounting systems feature 20mm base configurations suitable for all trapezoidal profiles, accommodating 0.4 to 0.7-gauge materials across single skin, twin skin, or composite industrial roof designs.

Load Distribution Principles: The corrugated nature of trapezoidal roofing requires specialized attention to load distribution across ridge and valley sections. High wind uplift applications, particularly on low-pitched roofs, necessitate enhanced fastening systems with three asymmetric twin thread screws per bracket to ensure structural integrity.

Installation Efficiency: Advanced mounting systems enable considerable time savings through optimized design features that provide floating capabilities and optimum stability during installation procedures.

Material Compatibility and Durability Factors

Trapezoidal roof mounting systems must accommodate diverse material compositions found in industrial roofing applications. High compatibility features include adjustable width, height, and angle functions to accommodate different trapezoidal roof dimensions, while corrosion resistance through SUS304 stainless steel clamps and anodized aluminum rails ensures extended durability.

The mounting hardware must withstand thermal cycling, wind loads, and environmental exposure while maintaining structural integrity over decades of service. Material selection becomes critical, particularly in industrial environments where chemical exposure or extreme temperatures may accelerate component degradation.

Commercial and Industrial Applications

Trapezoidal metal roof mounting systems find primary application in commercial and industrial solar projects, where large roof areas enable substantial energy generation capacity. These installations typically involve complex project requirements including structural engineering analysis, utility interconnection procedures, and compliance with industrial building codes.

Manufacturing Facilities: Industrial buildings with trapezoidal roofing often present ideal conditions for solar installations due to large unshaded roof areas and high energy consumption patterns. These applications require mounting systems capable of supporting extensive solar arrays while accommodating facility operations.

Warehouse and Distribution Centers: Large commercial buildings utilize trapezoidal roofing for cost-effective construction and weather protection. Solar installations on these structures require mounting systems that integrate seamlessly with existing roof drainage and ventilation systems.

Retail and Commercial Complexes: Shopping centers and commercial developments with trapezoidal roofing benefit from solar installations that reduce operating costs while maintaining architectural aesthetics. These projects demand mounting solutions that preserve building warranties and facilitate ongoing maintenance access.

Landpower Solar: Engineering Excellence in Specialized Mounting Solutions

Within this specialized market segment, manufacturers with deep technical expertise and comprehensive manufacturing capabilities provide crucial advantages for successful project execution. Landpower Solar has built its reputation through systematic focus on the engineering challenges that define trapezoidal roof mounting system performance.

Over 12 years of specialized development, Landpower has evolved from a regional manufacturer into an internationally recognized supplier of sophisticated mounting solutions. Their approach integrates advanced engineering methodologies with precision manufacturing processes to deliver systems that address the unique requirements of trapezoidal roof installations.

Manufacturing Capabilities and Technical Innovation

As a Global Leading Trapezoidal Roof Solar Mounting Company, Landpower's manufacturing operations reflect the precision required for specialized mounting applications. Their trapezoidal roof mounting systems undergo comprehensive engineering analysis to optimize material usage while ensuring compliance with international structural standards.

Advanced Manufacturing Processes: Sophisticated production equipment enables precise component fabrication that meets the tight tolerances required for trapezoidal roof applications. Computer-controlled forming operations ensure consistent clamp profiles that accommodate varying roof geometries.

Quality Control Systems: Comprehensive testing protocols verify component performance under simulated wind loads, thermal cycling, and corrosion exposure. These quality assurance measures ensure reliable long-term performance across diverse environmental conditions.

Customization Capabilities: Understanding that industrial buildings present unique requirements, Landpower maintains flexibility to modify standard designs for specific project needs without compromising manufacturing efficiency or delivery schedules.

Core Technical Advantages

Landpower's position as a Global Leading Trapezoidal Roof Solar Mounting and Ground Structure Supplier stems from several interconnected technical capabilities:

Engineering Expertise: Deep understanding of trapezoidal roof structural characteristics enables optimized mounting solutions that maximize installation efficiency while ensuring long-term reliability. Their engineering team addresses complex load path analysis and environmental factor considerations.

Material Science Proficiency: Expertise in aluminum alloy selection, stainless steel component design, and corrosion protection ensures mounting systems deliver decades of reliable service in challenging industrial environments.

Installation Optimization: Design features that simplify field installation procedures reduce labor costs and minimize project timelines. Pre-engineered connection details and standardized hardware reduce field complexity.

Comprehensive Product Portfolio: Beyond trapezoidal roof systems, Landpower offers integrated mounting solutions for ground installations, enabling single-source convenience for complex projects requiring multiple mounting approaches.

Product Applications and Market Segments

Landpower's trapezoidal roof mounting systems serve diverse industrial and commercial market segments, each presenting specific technical and economic requirements:

Heavy Industrial Applications: Manufacturing facilities requiring mounting systems that withstand industrial environments while accommodating equipment vibrations and thermal cycling. These installations often involve custom engineering for unique facility constraints.

Commercial Building Projects: Office buildings, retail centers, and institutional facilities utilizing trapezoidal roofing for cost-effective construction. These applications require mounting systems that maintain architectural aesthetics while delivering reliable performance.

Utility-Scale Industrial Installations: Large industrial solar developments that combine rooftop and ground-mounted systems for maximum energy generation capacity. These projects demand comprehensive mounting solutions that address varying installation requirements.

International Market Presence and Client Success

Landpower's global expansion reflects their ability to meet diverse market requirements while maintaining consistent quality standards. Their trapezoidal roof mounting systems have been deployed across multiple continents, supporting installations ranging from small commercial projects to large industrial developments.

Project portfolio diversity demonstrates Landpower's technical versatility and manufacturing scalability. From tropical installations requiring enhanced corrosion protection to industrial facilities in extreme climate zones, their mounting systems have proven durability across challenging environmental conditions.

The company's collaborative approach with installers, developers, and end customers enables optimized solutions that address project-specific requirements while leveraging standardized manufacturing processes for cost efficiency.

Innovation and Market Development

Continued market leadership requires ongoing investment in product development and manufacturing capability enhancement. Landpower's research initiatives focus on emerging technologies that improve mounting system performance while reducing installation complexity and project costs.

Current development programs include advanced clamp designs that accommodate wider ranges of trapezoidal profiles, enhanced connection systems that accelerate installation procedures, and integrated electrical components that simplify field wiring requirements.

Market Position and Industry Outlook

The convergence of industrial building construction trends, declining solar costs, and corporate sustainability initiatives creates favorable conditions for specialized mounting system suppliers. The global solar panel mounting structures market, valued at USD 13.1 billion in 2024, is predicted to reach USD 43.7 billion by 2037, growing at 9.8% CAGR, reflecting substantial opportunities for manufacturers with proven technical capabilities.

Landpower's positioning within this growth trajectory reflects strategic focus and operational execution. Their specialization in trapezoidal roof applications aligns with industrial building trends while their comprehensive manufacturing capabilities enable participation in broader market expansion.

The company's commitment to quality and innovation positions them advantageously for emerging opportunities in developing markets where industrial solar adoption accelerates. As demand for specialized mounting solutions increases, Landpower's technical expertise and international experience provide competitive advantages.

For comprehensive information about Landpower's trapezoidal roof mounting solutions and complete product portfolio, visit https://www.landpowersolar.com/