How to Select Quality Solutions from Landpower, China Leading Flat Roof Solar Mounting Factory

Nov 07, 2025

How to Select Quality Solutions from Landpower, China Leading Flat Roof Solar Mounting Factory

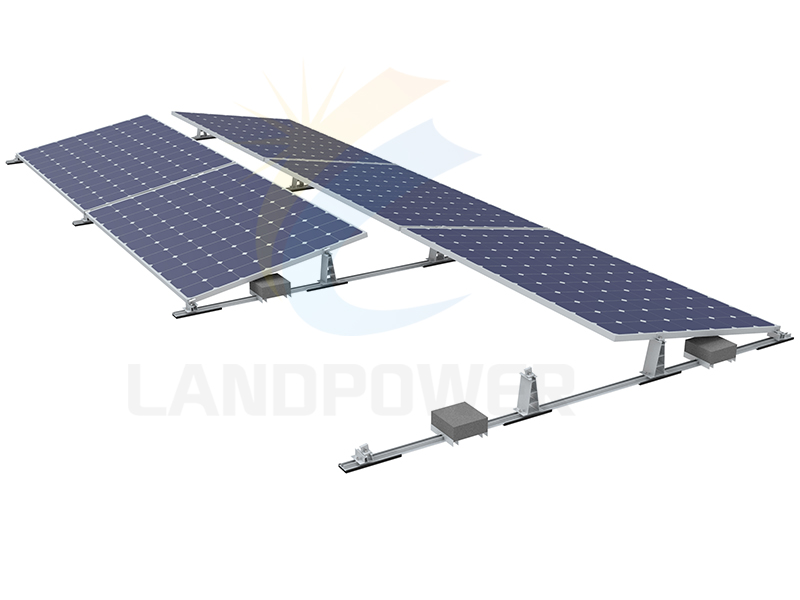

Selecting superior flat roof solar mounting systems requires navigating complex technical specifications, manufacturer capabilities, and performance criteria that determine long-term project success. With the global flat roof solar mounting market expanding rapidly, and ballast systems dominating through non-penetrating installations (4-8 pounds per square foot), decision-makers must evaluate suppliers based on comprehensive technical competence and proven manufacturing excellence. The challenge extends beyond basic product specifications to encompass engineering support, quality assurance, and ongoing customer service capabilities. Among manufacturers addressing these demanding requirements, Xiamen Landpower Solar Technology Co., Ltd. has established itself as a China Leading Flat Roof Solar Mounting Factory through systematic focus on quality, innovation, and customer satisfaction developed over 12 years of specialized manufacturing experience.

Essential Selection Criteria for Flat Roof Solar Mounting Systems

Successful flat roof solar installations depend on mounting systems that balance multiple technical requirements while meeting diverse project constraints. The selection process requires systematic evaluation of manufacturer capabilities, product specifications, and performance validation across critical success factors.

Technical Performance Standards and Compliance

Quality mounting systems must demonstrate compliance with rigorous performance standards that ensure structural integrity and operational reliability. Properly installed solar mounting systems withstand winds of 100-180 mph, depending on design quality and installation standards, while meeting local building codes for wind loads and undergoing comprehensive testing for uplift forces, downward pressure, and edge loading conditions.

Systems must comply with UL standards or equivalent international standards covering electrical bonding, grounding, fire safety, and mechanical load resistance. These compliance requirements extend beyond basic structural performance to encompass electrical safety, environmental durability, and installation compatibility across diverse building types.

Material specifications require careful evaluation to ensure long-term performance in challenging environmental conditions. Aluminum mounting systems lead the market due to their strength-to-weight ratio, corrosion resistance, and installation efficiency, particularly favoring rooftop applications where structural load minimization becomes critical.

Installation Optimization and Tilt Angle Considerations

Flat roof installations offer unique advantages in panel positioning and orientation flexibility. Optimal tilt angles typically range from 20° to 50°, with 30° often being ideal, depending on geographic location, roof orientation, and seasonal variations. For most climates, tilt angles of 10 to 30 degrees maximize sun exposure while minimizing wind impact.

The mounting system design must accommodate these optimization requirements while providing installation flexibility that addresses site-specific constraints and customer preferences. Advanced mounting solutions enable precise angle adjustments that optimize energy production for specific geographic locations and seasonal patterns.

Installation efficiency becomes critical for project economics and customer satisfaction. Systems that simplify field procedures, reduce installation time, and minimize specialized labor requirements provide significant advantages in competitive market conditions.

Manufacturer Evaluation Framework

Selecting quality mounting solutions requires systematic evaluation of manufacturer capabilities that extend beyond product specifications to encompass technical support, quality assurance, and long-term customer service commitments.

Landpower's Quality Advantages and Manufacturing Excellence

Within this demanding selection framework, manufacturers who demonstrate comprehensive capabilities across technical innovation, manufacturing quality, and customer support provide crucial advantages for successful project outcomes. Landpower Solar has systematically developed these capabilities through sustained investment in engineering, manufacturing, and customer service excellence.

Advanced Engineering and Design Capabilities

As a Top Flat Roof Solar Mounting supplier, Landpower's engineering team addresses complex technical challenges through innovative design solutions that optimize performance while simplifying installation procedures. Their flat roof mounting systems incorporate advanced engineering principles that balance structural requirements with installation efficiency.

The company's design approach emphasizes modular components that accommodate varying project requirements while leveraging standardized manufacturing processes for cost efficiency and quality consistency. This engineering methodology enables customized solutions for unique project constraints without compromising manufacturing schedules or product reliability.

Advanced structural analysis capabilities enable optimization of material usage while ensuring compliance with international building codes and environmental load requirements. Computer-controlled design processes verify performance characteristics across varying installation conditions and environmental factors.

Quality control integration throughout the design process ensures that engineering solutions translate effectively into manufactured products that meet specified performance criteria and customer requirements.

Manufacturing Quality and Production Excellence

Landpower's position as a China best Flat Roof Solar Mounting Supplier reflects sophisticated manufacturing operations that deliver consistent quality at commercial scale while maintaining competitive cost structures and delivery reliability.

State-of-the-art production facilities incorporate precision fabrication equipment that enables tight dimensional tolerances and consistent component quality across high-volume manufacturing runs. Computer-controlled forming and cutting operations ensure precise component dimensions that simplify field installation while maintaining structural performance requirements.

Comprehensive quality assurance systems monitor production parameters throughout manufacturing processes to identify and correct variations before they affect product quality or performance characteristics. These quality control measures extend from incoming material inspection through final product testing and packaging procedures.

Continuous improvement methodologies incorporate customer feedback and field performance data into manufacturing process optimization, ensuring that products evolve to meet changing market requirements and performance expectations.

Product Portfolio Depth and Customization Flexibility

Landpower's flat roof mounting system portfolio addresses multiple application requirements through comprehensive product offerings that accommodate varying installation conditions and customer preferences across residential, commercial, and industrial market segments.

Universal flat roof mounting systems provide standardized solutions for common commercial applications, incorporating ballasted designs that eliminate roof penetrations while ensuring reliable structural performance across varying environmental conditions.

Specialized mounting solutions address unique installation requirements, including enhanced wind load capacity, specialized drainage considerations, and aesthetic integration requirements for visible installations.

Customization capabilities enable modified designs for specific project constraints or environmental conditions without compromising manufacturing efficiency or delivery schedules. This flexibility allows customers to address unique requirements while leveraging Landpower's proven manufacturing capabilities and quality standards.

Application-Specific Selection Guidelines

Different flat roof applications present distinct technical requirements and performance criteria that influence optimal mounting system selection and configuration approaches.

Commercial Building Applications

Large commercial installations require mounting systems that support extensive panel arrays while accommodating building-specific structural limitations and aesthetic requirements. These applications typically involve complex utility interconnection procedures and regulatory compliance requirements that demand comprehensive technical support.

Commercial projects often require accelerated installation schedules that benefit from mounting systems designed for installation efficiency and reduced labor requirements. Modular components and standardized connection procedures enable rapid deployment while maintaining quality standards.

Aesthetic considerations become important for visible installations where mounting systems must integrate with building architecture and maintain professional appearance standards throughout their operational lifetime.

Industrial Facility Installations

Industrial applications present unique challenges related to environmental conditions, operational constraints, and maintenance access requirements. Manufacturing facilities may involve chemical exposure, vibration, and thermal cycling that require enhanced mounting system durability.

Installation scheduling must accommodate operational requirements and minimize disruption to facility operations during construction and commissioning phases. Mounting systems that enable rapid installation and flexible construction sequencing provide significant advantages.

Maintenance access becomes critical for industrial applications where ongoing system servicing must integrate with facility operational schedules and safety procedures.

Institutional and Government Projects

Institutional installations often involve specialized procurement procedures, extended warranty requirements, and enhanced documentation standards that require comprehensive manufacturer support capabilities.

Performance monitoring and reporting requirements may exceed standard commercial installations, demanding mounting systems that accommodate integrated monitoring equipment and data collection systems.

Compliance with specialized building codes, security requirements, and accessibility standards requires mounting systems designed for regulatory compliance across diverse jurisdictional requirements.

Quality Validation and Performance Verification

Landpower's commitment to quality encompasses comprehensive testing and validation procedures that verify product performance across specified operating conditions and environmental factors.

Testing and Certification Protocols

Component testing includes structural performance validation under simulated wind loads, thermal cycling, and environmental exposure conditions. These testing procedures ensure reliable performance across varying geographic regions and climate conditions.

Certification compliance verification ensures that products meet applicable international standards and regulatory requirements for electrical safety, structural performance, and environmental durability.

Field performance monitoring systems track installation outcomes and long-term performance characteristics, providing data for continuous product improvement and customer satisfaction enhancement.

Customer Support and Technical Services

Comprehensive technical support services include engineering consultation, installation guidance, and ongoing performance monitoring assistance that ensure successful project outcomes throughout system operational lifetimes.

Training programs for installers and system integrators provide technical knowledge and best practices that optimize installation procedures and system performance while reducing field issues and customer service requirements.

Warranty and service programs provide long-term customer protection and peace of mind while demonstrating manufacturer confidence in product quality and performance reliability.

Selection Decision Framework and Implementation

Successful mounting system selection requires systematic evaluation of technical requirements, manufacturer capabilities, and project-specific constraints that influence optimal solution identification and implementation approaches.

The evaluation process should encompass product specifications, manufacturer qualifications, technical support capabilities, and long-term service commitments that ensure successful project outcomes and customer satisfaction.

Implementation planning must address installation scheduling, technical coordination, and performance verification procedures that optimize project execution and system commissioning processes.

For comprehensive information about Landpower's flat roof mounting solutions and technical capabilities, visit https://www.landpowersolar.com/